Oleogels and tasty cells

Vignette of the Laboratory of Lipids and Soft Matter, headed by Dr. Maya Davidovich-Pinhas at the TECHNION Israel Institute of Technology

Background:

What is an oleogel? Oleogels may be thought of as the fatty counterparts to hydrogels, which are more familiar than one might think. Hydrogels are classified as substances whose bulk material is made up mostly of water (~90%) and are “solidified” by dissolving some coagulating agent such as gelatin that subsequently forms a mesh with itself to provide structure to the gel. I am sure that many readers here are familiar with such a substance from a common childhood snack called JELL-O. JELL-O actually gets its name from the coagulating agent known as gelatin, which is a simpler form of a common structural protein in the body known as collagen. By dissolving gelatin into water, the individual protein monomers (or repeating units) begin to form meshes of polymer networks that give the overall structure its solid-like state and mechanical properties. Similarly, oleogels are the fat (oleic acid) based equivalent to these structures. By generating different formulas of coagulants and solvents (fat or water) that are combined at variable temperatures and concentrations, researchers can create hydrogels and oleogels with finely tunable mechanical and chemical properties. This allows for a wide range of applications ranging from the production of food additives for cellular agriculture and even novel drug delivery systems! This is exactly what the Laboratory of Lipids and Soft Matter is focused on in their research.

Open question:

Scalable production motifs for creating cultivated meat, such as 3D printing, require specific rheologic [liquid state mechanical] properties to properly balance speed, accuracy, and cell viability during printing. While creating oleogels or hydrogels offers a lot of control over these mechanical properties, there are limitations in how fine-tuned the material is for producing distinct cultivated meat products. In a recent publication, the Laboratory of Lipids and Soft Matter describe a combinatorial oleogel and hydrogel, termed “bigel”, that displayed a greater capacity for fine-tuning than the individual gel types on their own. This group set out to determine what parameters of a bigel formula correlated to specific mechanical properties to allow researchers and companies to produce unique mechanical properties for distinct 3D-printed cultivated meat products.

What they did:

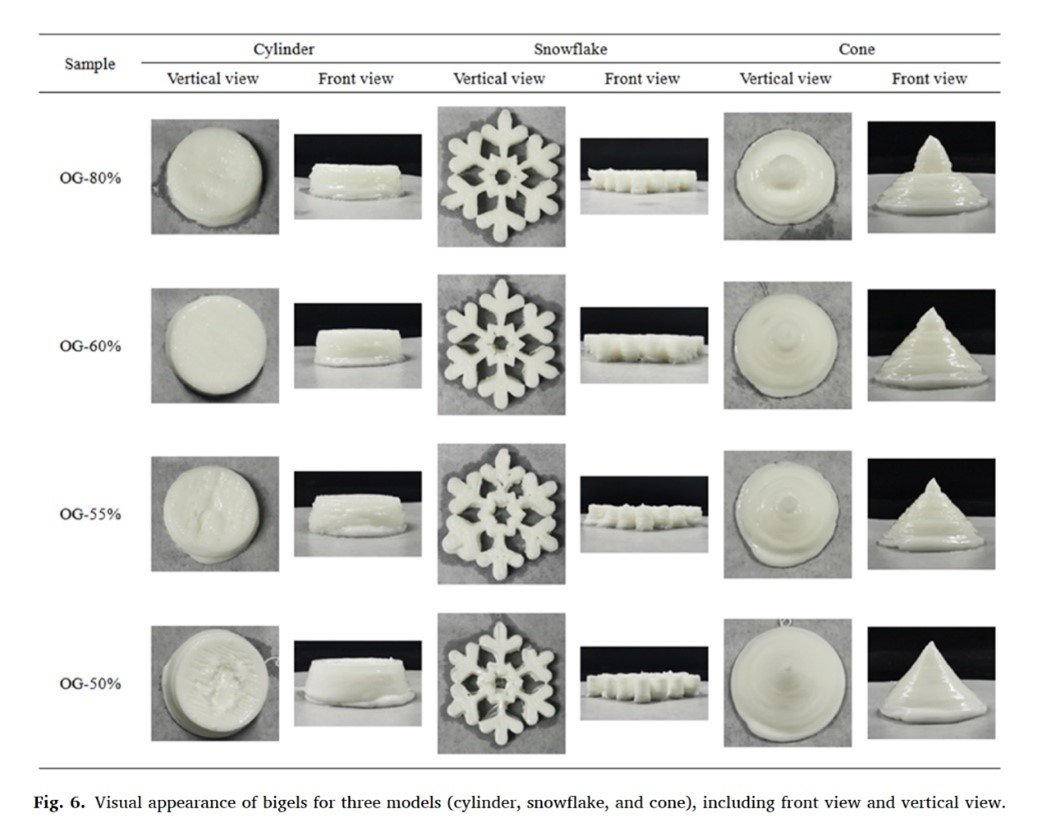

Researchers chose two edible coagulating agents that are generally regarded as safe (GRAS) for human consumption to produce their tunable gels. The hydrogel component of their bigel system was produced using hydroxypropyl methylcellulose (HPMC), which is a common component in eye drops and orally administered medications. Meanwhile, oleogels were created using beeswax to provide their mechanical structure. Bigels are mixed in either an “oil in water” formulation (O/W) where the majority of the gel is made of water, with oil droplets intermixed as a solute, or conversely, you have “water in oil” (W/O) where oil is the majority. Bigel formulas of different concentrations were prepared using an emulsifier and then tested for their microstructure and rheologic properties. As shown in figure 6 taken from this lab’s publication “Novel bigels constructed from oleogels and hydrogels with contrary thermal characteristics: Phase inversion and 3D printing applications” (DOI: 10.1016/j.foodhyd.2022.108063), different 3D printed constructs were created to test the efficacy of these bi-gel formulations for food production. The hollow snowflake model displayed the capacity for each formula to print and maintain the shape of complex structures and the cone structure shows the ability to print small areas. Overall, W/O bigels with 60% oleogel structure displayed the best printing capacity using these metrics.

Why it’s important:

This work details how to produce fats with highly tunable mechanical properties for tailored cultivated meat applications. different percentages of oleogels provide visually distinct properties that allow for the formation of different types of products from solid-state fats, such as butter, to viscoelastic (semi-solid) ones like whipped cream. This allows researchers to produce familiar products that consumers desire while having more control over the chemical makeup of these products as it relates to both flavor and nutrition. Interestingly, this process allows for the production of solid and semi-solid fat products, usually associated with less healthy nutritional profiles, using liquid at room temperature fats such as vegetable oils. This unique feature could allow for the production of meats or even baked goods with healthier fats that don’t sacrifice texture and cooking utility. This versatility also allows for the tuning of key nutrient absorption from eating these fats as well. It has been noted that lipid-based delivery systems for insoluble therapeutics offer a promising delivery system for adequate absorption through the GI tract. It is therefore a feasible and intriguing idea that oleogels or bigels may be adapted in similar ways to allow for the loading of key nutrients not generally found in meat while boosting their absorption efficiency for the consumer. One might think of this concept as the spiritual successor to genetically engineered crops such as golden rice, which aimed to solve specific dietary issues of areas that are not able to naturally produce crops high in the vital nutrient beta carotene. Ultimately, this research underscores a unique, and often overlooked, aspect of cellular agriculture that poises itself to not only recreate the foods of our varied cultures that have become central to our way of being but that we can move beyond the limits of animal agriculture to improve the nutritional benefits of eating these products as well. This exciting future allows for the ethical and environmentally friendly production of meat that could make us healthier while still enjoying the foods we love.

Written by Christopher Anderson, Ph.D., Helikon Associate